Master-Data-Management(MDM)

Asset data stored in multiple applications (like ERP, Business Intelligence Software's etc.) shall be maintained current at all times to enable effective operation of the business. For the business to be effectively monitored changes to facilities and equipment require to be maintained promptly.

Master Data Management mainly needs services like Customer Data Integration and Product Information Management which is our core business.

Master Data Management Process involves data Analytics, Data synchronization & Quality checking. MDM helps to maintain more accurate and long-lasting records and improves business analytics and intelligence.

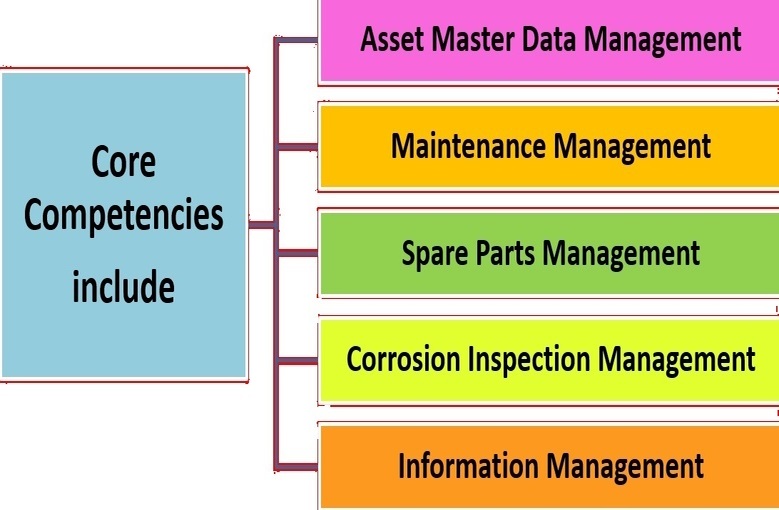

Our core services include

o Data Cleansing

o Data Enrichment

o Data Classification

o Taxonomy Development

o Schema Mapping

o Asset deactivation & deletion

o Exception Based Verification Process

o Spare parts management(E-SPIR)

o Computerized Maintenance management using CMMS

o Build Maintenance strategy( task list/standard text) using RCM,RBI reports

o Corrosion inspection Management using PACER/CIMS

o Information Management

o Engineering data ware house(EDW)

New Asset Registration:

o Data enrichment-Collect maintainable Tag numbers from engineering drawings like PEFS, SLD,layout etc.

o Data classification-Preparation of Asset Register & Buildup Asset Hierarchy tree.

o Identification of safety critical element using HSE case, Hazard area drawing and assigning barriers

o Develop Step by step maintenance craft procedure for each items as per equipment criticality

o Data verification-Check Entries and quality checking

o Uploading the asset data into SAP system

Physical data verification:

o Existing Asset Register verification- Download existing data from SAP & verify with respective drawings. (PEFS, UEFS, SLDs , GS drawings, Line)

o Physical verification of the tags at site to compare data with Drawings and SAP.

o Resolve the data conflictness in the customer data base and equipment and material ordinal information’s.

o Correct the data, develop asset hierarchy and upload the data into SAP system

Maintenance Management:

Each asset registered in SAP shall be reviewed for the need of routine maintenance activities to ensure and maintain technical integrity.

Routine maintenance activities are identified based on equipment manufacturer recommendations, RCM (Reliability Centred Maintenance) analysis

Our services include

o Developing step by step new maintenance craft procedure for each item as per equipment criticality

o Defining maintenance frequency on equipment manufacturer recommendations

o Keeping track of preventive maintenance jobs, including step-by-step instructions or check-lists.

o The following details will be updated on the templates for Maintenance Plan linking

o Maintenance Task List

o Standard Text

o Task List Groups

o Groups and Group counters

o Upload the maintenance plan into SAP system

Spare Parts Management:

Spare parts Management plays an important role in achieving the desired plant availability at an optimum cost. It has been observed in many cases that the non-availability of spare parts, as and when required for repairs, contributes to as much as 50% of the total down time. This amply signifies the vital importance of spare parts management in any organization.

Our services include

o Acquire BOM(spare parts) details from vendors required for equipment's in standard format spreadsheets( E-SPIR). E-SPIR is a software package for obtaining spare parts information from equipment suppliers in a standard format.

o Compile and organize data and check spare parts along with OEM manual

o Review spare parts along with part list drawings and BOM for each item

o Categorize the spares parts into following:

o Insurance Spares

o Commissioning Spares

o Initial Operating Spares

o Operating Spares

o Getting the spare parts SAP coded for linking in SAP

• Corrosion Inspection Management

CIMS is the corporate computerized inspection and corrosion management tool that is used for storage of related data and subsequent trending report for asset integrity purpose. SAP & CIMS are designed to work in collaboration with each other.

All tag/ equipment will be registered in SAP with a link provided to CIMS.

CIMS data comprises of static equipment's like Tanks, Vessels, Heat exchangers, on plot piping, Relief valves etc.

Our services Include:

o Preparation of CIMS data in standard format spreadsheets taking reference from tags registered in SAP

o Gather technical details from general arrangement drawings and populate the templates

o Check Entries and quality checking

o Upload standard templates into CIMS system for storing data for an individual equipment item

o Modification of existing data in CIMS system based on physical verification reports